Grinding in Ball Mills: Modeling and Process Control

Grinding in Ball Mills: Modeling and Process Control ... Ball mills, grinding circuit, ... The speed of rotation of the mill determines three basic types of operation

WhatsApp)

WhatsApp)

Grinding in Ball Mills: Modeling and Process Control ... Ball mills, grinding circuit, ... The speed of rotation of the mill determines three basic types of operation

optimization of a ball mill operation, ball mill operate methods. ... High to make ball mill operation, the grinding effect, ...

Mini Planetary Ball Mill Lab ball mills,Lab... Mini Planetary Ball Mill is an ideal facility to acquire research samples for research institutes, universities as ...

Ball mill application Ball mill grinding is a highly energy consuming process and the ECS ... wet ball mill operation in gold milling; grinding operation ...

OPERATIONAL EXPERIENCE FROM THE UNITED STATES'' ... ball mill operation has been established throughout the history of ball mill cement grinding.

The Continuous Ball and Pebble Mill grinding units range from ... type Ball Pebble Mills. ... cool during the grinding operation is achieved in the minimum ...

Xinhai grinding mill has excellent energy saving ability, Xinhai, as ball mill manudactures, the energysaving ball mill up to 30%, great ball mill working principle ...

From industrial grinding and milling Strommashina Corp. supplies ball mills and ball mill ... to the tube ball mill grinding type of continuous operation.

Common types of grinding mills include Ball Mills and Rod ... Wet grinding ball mill in mining operation. Balls within mill retain their high grinding efficiency ...

Ball Mill and Grinding Circuit Preparation for StartUP The following items must be checked before the equipment in the Grinding Circuit is started. Check the ore ...

Cement grinding Vertical roller mills versus ball ... to the ball mill system and has increased its share ... enabling a high grinding efficiency and stable operation.

Denver Instruction Operation Manual Download ... used in the SubA Unit Cells when they are installed in the ball millclassifier ... to the batch grinding mill.

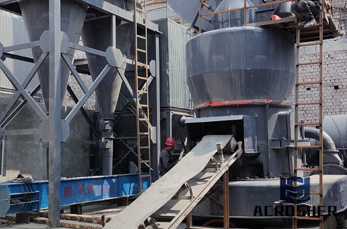

ball mill, grinding equipment, milling, crushing equipment ... ... A grinding mill is a unit operation designed to break a solid material into smaller pieces.

Ball Grinding Mill mineraltechnologyGrinding Mill Ball Crusher Ball Grinding Mill Ball Grinding Machine Rugged construction, reliable operation 2 .Easy installation

operation experiences cement grinding mill_New orders for Gebr Pfeiffer in South AsiaGebr Pfeiffer has ... A high efficiency and energy saving ball mill with ...

about the mill operation is vital. An innovative tool which can ... the degree of grinding ball fill and pulp position for timely decision making and actions.

The ball mill is used for grinding materials such as coal, pigments, and feldspar for pottery. ... it is suitable for both batch and continuous operation, ...

Installation is complete, after passing test, and then test run empty car. The ball mill trial operation should be by skilled operators shall be responsible for ball ...

FL ball mill for cement grinding. Versatile system based ... the noise emission from the mill during operation. The shell lining in the second compart

As a result of today''s requirements for maximizing grinding throughput, ball mill with higher power demand has been developed and ... Before ball mill operation, ...

In filling mill by grinding balls on 40 ... The operating principle of the ball mill consists of ... Most of the energy useless lost during ball mill operation, ...

View Perofrmance testing of ball mills from EE 105 at Ut State University College of Eastern Ut. TP03. Operation and Optimisation of Bell Mlll Grinding Page 3 ...

Effect of operating variables on the energy efficiency of ball mill analyzed. • Rates of particle breakage and production of fines per unit power input considered.

Operation aim of ball mill grinding process is to control grinding particle size and circulation load to ball mill into their objective limits respectively, while ...

WhatsApp)

WhatsApp)